It has been a while since my last post, mainly due to all of my free time being used up with doing bike-related things, leaving me without the time to write about them.

Brompton:

I noticed that in addition to the noise from my folding pedal (which I can live with based on the cost of a replacement), There was some noise coming from the bottom bracket. The Brompton uses a FAG-type cartridge bottom bracket, and the replacement part is relatively expensive. I decided to opt for a cheaper generic bottom bracket cartridge with Shimano-style splined cups.

The standard Brompton bottom bracket, with soft plastic cups

I initially expected that I’d be able to remove the old bottom bracket with a hammer and punch because I didn’t have to worry about damaging it. However, I discovered that the cups on the original bottom bracket are made of a fairly soft resin which simply splits when approached this way. I eventually bought the proper tool and the bottom bracket co-operated with the removal process after that. The bike is quieter now, but there is still a fair bit of noise from the (non user-serviceable) folding pedal.

The new bottom bracket cartridge, sitting in the bike.

In other Brompton news, lovely girlfriend has managed to get hold of a 2000 model L5 (equivalent to an “M5L” in the modern nomenclature). This model comes with the Sturmey Archer 5 speed Sprinter hub, which offers a good gear range with a price, it requires particularly perfect indicator rod adjustment to get all of the gears to work at the same time. I believe that the right-hand cone needs adjusting slightly, as I am only able to consistently get gears 1,3,4,5 or gears 2,3,4,5 to work at the same time.

The L5 also needed a new front brake cable, indicator rod and rear mudflap, which have all since been fitted and the bike is currently working very well. The Marathon Plus tyres it has make the bike feel noticeably smoother and faster than my Brompton, and the wider gears range is pleasant too. Hopefully Brompton will see sense and start speccing the X-RF8 hub as an option in the near future. It also came with the special Brompton version of the Brooks B17 saddle, a luggage block and an older version of the Touring Pannier (now T-bag) from back when they were made by Carradice.

DL-1:

After fitting the anti-rotation washers to the back wheel last week, I rotated the reaction arm slightly to compensate for the re-positioning of the axle in the frame. In the process of doing this, I inadvertently over-tightened the left-hand cone making the ride feel “draggy.” Thankfully this was an easy fix once the wheel was out thanks to the two grooves on the “washer” which locks into the cone on the other side of the drum brake. This allowed me to adjust the brake position and re-tighten the locknut without it tightening the cone at the same time.

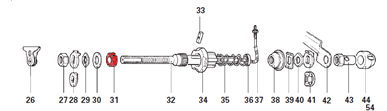

Taken from the X-RD3 manual, the special washer (31) which sits between the cone (not shown) and locknut (29) is highlighted in red.

because this job was non-urgent, I put it off for quite a while. Now the bike is back to normal I really appreciate just how wonderful it is to ride.

Kona Africa Bike:

After giving this bike to lovely girlfriend, she never really felt safe in start-stop traffic because of the coaster brake preventing her being able to rotate the pedals into an ideal position to set off. In the end, we decided that replacing the 3 speed Nexus hub with a roller-brake version would be best. I disassembled the wheel and intended to use the old spokes with the new hub, only to find out the flange diameter of the new hub was slightly bigger and the old spokes were too long. After ordering some new spokes which were a few mm shorter, I built the wheel up without too much trouble (no severe dishing required as with derailleur gears).

The new wheel, before the cable had been installed. Note the brake arm with the hold for the cable clamp to sit in.

The roller brake idea is particularly good, unlike Sturmey’s drum brakes, the roller brake is a completely separate module which sits on some splines on the left hand side of the hub. If the brake fails, or you want to fit a better version, it can simply be replaced without re-building the wheel. The brake slots onto the splines and is held in with a simple locknut. Other than that, the mechanism is similar to Sturmey Archer drum brakes, except they don’t need a special brake cable, the barrel adjuster and cable clamp come with the brake, all you need to use is a standard brake cable. Upon testing the bike, the roller brake provided an impressive amount of stopping power for a low-maintenance, non-performance-oriented component. This is one of the most basic model roller brake Shimano makes

Raleigh Twentys:

I recently acquired a pair of Raleigh Twentys which I am reconditioning on behalf of a few friends. One is a 1974 “Shopper,” the other is a 1980 model with a rear Dynohub. I tested the Dynohub with my Brompton lights and it was perfectly able to power the front and rear LED lights despite its lower official power rating than modern dynamo hubs.

The Dynohub AWG on from the 1980 Twenty

A previous owner has attempted to fit road bike caliper brakes and drop bar brake levers to the 1980 Twenty, which will have to be swapped out for the appropriate brakes. The rear wheel had a broken spoke, but I happened to have some spokes of the right length already due to a mistake made when ordering spokes for a Twenty wheel last year. Other than that, both bikes only need a bit of de-rusting, new chains and new tyres and they will be ready for their new owners. So far I have only serviced the rear wheels of each bike.

The 1974 AW hub, after disassembly, cleaning and re-assembly.

Universal Folding Bike:

This is another bike I am servicing for a friend, a Universal folding bike with a Shimano “333” 3-speed hub and 20 inch (406 mm) wheels. The riding position is quite comfortable and upright, making the bike an ideal runaround machine. The 333 hub is in good condition, although the cable has rusted seized. 333 hubs were a lot less popular than Sturmey Archer hubs, meaning a replacement cable was not forthcoming. Thankfully, I should be able to come up with a suitable bodge using a cable clamp nut/bolt and a Sturmey Archer gear cable. Other than that it just needs a bit of rust removal, new tyres and a new chain.

The 333 hub shifts via a bell-crank and push-rod mechanism in a similar way to modern Nexus 3-speed hubs.

Ah, the 333. My three-speed afficionado friends cringe at the sound of those numbers. I'm told that the hubs work fine...when they work. Just hard to impossible to get replacement stuff for them, and Shimano didn't provide the same level of exploded-drawingness that S-A did for their IGH hubs. (Though I have seen a drawing of the 333 in an old Schwinn service manual from the early '70's. They used to use S-A hubs for their 3-speeds until the Shimano steamroller got going.)

ReplyDeleteIf you find any cheap Bromptons please feel free to ship me one to Portland. Or a Carradice Camper Longflap in decent shape.

@Adventure!

ReplyDeleteI know what you mean, people don't have the same affinity for these hubs as the SA ones. Fewer 333s have survived, which is probably part of the problem, they just aren't as good. Internally they are very similar, but without the easy availability of replacement parts that the AW has, it is a much less viable option. Eventually I may end up building up a new wheel with an AW hub for it instead.